News

How to fix decking to a support structure

The correct fixing as specified by the fastener manufacturer, to suit the application of fixing to cold rolled thin gauge purlins, hot rolled steel sections or timber supports.

Fasteners are a vital component to ensure the safe installation of [decks]. The correct fixing as specified by the fastener manufacturer, to suit the application of fixing to cold rolled thin gauge purlins, hot rolled steel sections or timber supports.

Self drilling/self tapping screws (commonly known as drill screws), must be a minimum 5.5mm diameter, available in carbon steel or austenitic stainless steel, and must resist all pullout, pullover and shear forces.

For compliance with non fragility requirements, fasteners should be positioned 50mm minimum in from the deck sheet end.

Alternatively:-

Shot fired pins may be installed into hot rolled steel sections, subject to minimum flange requirements, as specified by fastener manufacturer.

Side lap stitching screws may be replaced with rivets, as specified by fastener manufacturer.

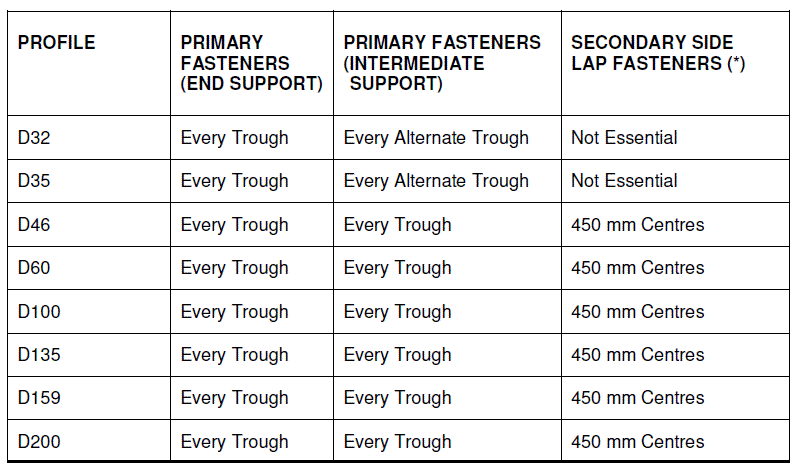

[Decks] are fixed to the support structure from above the deck. The table below indicates generic recommendations, which must be checked against specific project requirementsm especially for high wind suction loads, which may require more than one screw per trough, and reduced side lap centres when the deck acts in diaphragm.

(*) Fixing centres for side laps may be required to be reduced, subject to diaphragm design.

Where the deck is required to provide a vapour barrier, screws must be supplied with a sealing washer. If a separate vapour control membrane is installed above the deck, screws can be installed without washers.

Self drilling screws are primarily used, suitable up to specific support flange thickness specified by fastener manufacturers. Where flange thickness is greater, self tapping screws are required, installed into a pre drilled pilot hole.

Aluminium decking

For aluminium roof decking, the fastener frequency is the same as for

steel decks. However to prevent bi-metallic corrosion, austenitic

stainless steel screws must be installed. A simple site test to

determine the grade of screw is to check with a magnet, as stainless

steel screws are non magnetic.

Tubular support structure

Decks can be installed above tubular structure, however this requires special consideration.

The bearing support will be minimal, thus increasing the bending and reaction moment over the support.

Location of screws is more difficult, any deviation from the apex position could cause the screw to twist out of alignment.

The sheet end will be visible, any deviation in panel length tolerance may indicate staggered sheet ends. Manufacturing tolerances on length allow +10mm/-5mm up to 3000mm, and +20mm/-5mm for lengths over 3000mm.

Therefore for tubular structure it is recommended that a flat plate is added, to provide a normal 100mm minimum flat bearing support.

Timber support structure

Screw installation into timber taken from BS 5268:Part 2: 2000

Timber may be treated with preservatives that could have an adverse

effect on carbon steel screws; therefore it is recommended that

austenitic stainless steel screws are specified for installation into

timber, ensuring a minimum embedment and minimum edge distances as

indicated below.

The screw diameter may be taken as the screw root diameter.

Concrete support structure

It is not recommended to drill directly into concrete purlins, unless

agreed satisfactory by a structural engineer. Straps can be added to

connect a top hat section for the support and attachment of decking.

Masonary wall support structure

The level of masonary wall can not be guaranteed, therefore a steel

section should be added to support decking. This allows the deck to be

fixed with standard Tec fasteners, or shot fired pins to a suitable

flange thickness.

For further information please do not hesitate to get in touch with our Technical Department

【 Go Back 】 | 【 Print 】 | 【 Close this window 】